Common small engine problems, such as failure to start or rough idling, frequently stem from fuel delivery obstructions or dirty carburetors. Additionally, checking the spark plug gap and ensuring the air filter is clean solves a significant percentage of performance issues.

Nothing frustrates an owner more than an small engine problem that won’t go away. First, check the fuel level. It sounds simple. However, it is a common oversight. Next, check the kill switch. Safety levers must be fully engaged. Therefore, inspect cables for stretching. If these check out, suspect the spark plug. A fouled plug prevents ignition. Thus, removing and inspecting it often reveals the answer.

The Starting Struggle one of the most common small engine problems

Addressing Rough Running

Does your small engine problem sputter? This usually points to airflow or fuel flow. First, inspect the air filter. A clogged filter chokes the engine. Consequently, the engine loses power. Replace it immediately. However, if the filter is clean, look at the fuel cap. The vent might be clogged. This creates a vacuum in the tank. As a result, fuel stops flowing. Loosen the cap. If the engine smooths out, replace the cap.

The Vibration Problem

Excessive vibration causes fatigue. Furthermore, it damages components. Often, a bent blade or crankshaft causes this. This happens after hitting a rock. Therefore, stop the engine immediately. Do not run a vibrating engine. It poses a safety hazard. Instead, bring it to Brooks Factory Direct Trailers. Our team measures runout accurately. We determine if the shaft needs straightening or replacement.

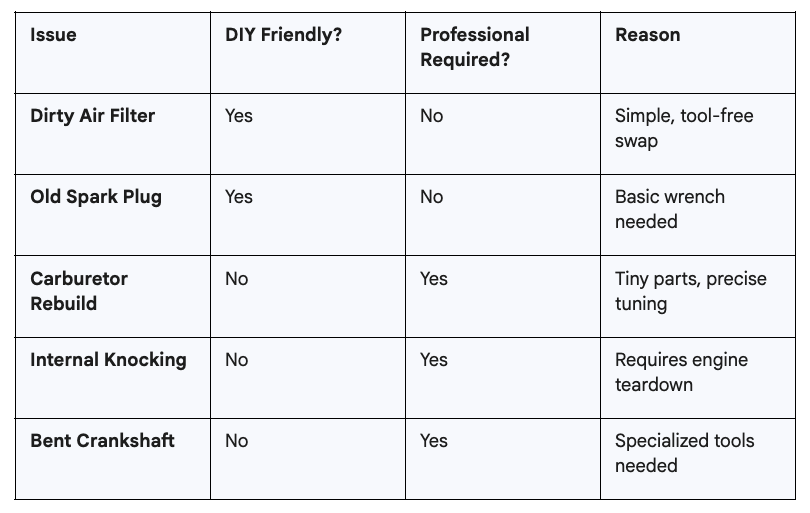

Professional vs. DIY Repair Guide

The Value of Expert Eyes

You might fix a symptom but miss the disease. For instance, replacing a plug might start the engine. However, if the old plug was oil-fouled, you have internal wear. A professional small engine repair technician identifies this. Consequently, you save money on future repairs. We utilize the latest methods at our Ontario and Oswego shops. Thus, we ensure your equipment operates safely.

Frequently Asked Questions (Q&A)

Q: Why does my engine stall after a few minutes?

A: This often indicates a clogged fuel cap vent or an overheating ignition coil. Therefore, the engine dies once hot.

Q: Can I clean a paper air filter?

A: No, you should replace paper filters. Blowing them out with compressed air tears the paper. This lets dirt in.

Q: What causes the starter cord to snap back?

A: This “kickback” usually results from a sheared flywheel key. Consequently, the ignition timing is off.

Q: How do I know if my fuel is bad?

A: Fuel older than 30 days smells like varnish and loses volatility. Therefore, drain it and refill with fresh gas.

Q: Why is my engine leaking oil?

A: Leaks often come from blown gaskets or loose bolts. Thus, a thorough cleaning and inspection is necessary to find the source.

Don’t let equipment failure slow you down; contact Brooks Factory Direct Trailers for premier small engine repair services in Ontario and Oswego.

For more resources look at Briggs & Stratton for more information